Blow glass at home. Glassblower workshop - we make a vase with our own hands

* Calculations use average data for Russia

Glass is considered to be one of the most interesting and spectacular materials used for making souvenirs. Glass is characterized by relatively low cost, plasticity and high ductility to processing. Glass can be used to make products of the most various forms and flowers, from simple tableware to real works of art that will adorn any collection. Meanwhile, the production of glass products is not a simple matter. Rather, on the contrary, it is a complex process that requires the master to have extensive experience and professionalism. In addition, he must also have good artistic taste, otherwise his glass products will not be in demand. An additional advantage of glass products is that due to the specifics of the process of its production, which is carried out entirely by hand in small enterprises (and even in large factories this process cannot be fully automated), each finished product is one of a kind and inimitable. No less popular among consumers are glass jewelry, which may not be as durable as natural stone products, but are very beautiful and original. The range of glass products is almost limitless. These can be glass bouquets, and small vases, and figurines of animals, and decorations, and signs of the zodiac, etc.

Manufacture of glass products by hand

The technological process of manufacturing glass products in small glass-blowing workshops involves the use of exclusively manual labor. On the one hand, this greatly complicates the production and increases the cost of the product, and on the other hand, it raises the value of such a glass souvenir in the eyes of buyers. Simplified, the process of "manual" manufacturing can be represented as follows: first, the master heats the workpiece, which is called glass core, and then, using a special tool, gives it one shape or another. This procedure is not only laborious, but also dangerous. The production of one complex product can sometimes take several hours.

Before starting work, clean workplace from dust and debris, so that foreign inclusions do not get into the glass. Then, a glass dart (glass dart) of the required shades, length and thickness is laid out on the desktop in front of the master. Steklodrot represents sticks from color glass up to 40 cm long and with a diameter from three to six mm. A special burner is used to melt the glass core. First, the master heats two glass rods to a plastic state, and then makes a part of the future figurine from this mass, giving the workpiece the necessary shape in the process. Other parts (eg legs, heads, tails) are made from glass rods of different thicknesses and/or colors. In this case, the same technology is used: first, the glass is heated on a burner, and then small parts are attached to the base body. At the last stage, the final shape is given to the figure by gluing ears, eyes, clothes, noses and other elements to it. Finally, the finished figurine is left to cool completely, and then checked for defects. To do this, the master or controller simply carefully examines the product in the light. If the marriage is not detected, the figurine is packed and sent to the warehouse. If any mistakes were made during the work, then small cracks are clearly visible inside the figure. Such a product is recognized as defective and sent for processing. Depending on the qualifications and experience of the craftsman, as well as the complexity of the figurine, it can take from twenty minutes to several hours to make it. According to a similar scheme, other souvenir and gift products are made in small workshops, such as vases and Christmas decorations, but in this case the glass is inflated to form a cavity inside the product.

Glass workshop: premises and equipment

Earn up to

200 000 rub. a month, having fun!

2019 trend. Intelligent entertainment business. Minimum investment. No additional deductions or payments. Turnkey training.

So the size start-up capital for opening your own production of glass products directly depends on the planned production volumes. Experts say that it is better to start such production with a glass-blowing workshop for at least fifteen jobs. First of all, you need a suitable space. It should be spacious enough and comfortable for work. The recommended area should not be less than 50 square meters. meters, and the height of the ceilings is at least 3-3.5 meters. The floor of the workshop is best covered with linoleum or vinyl chloride tiles. With a soft floor covering, there is less risk that a piece of glass that has fallen on the floor will break into small pieces. The arrangement of furniture and equipment in a glass-blowing workshop is subject to special requirements related to the specifics of production, which must be taken into account when choosing a room. So, for example, work tables are arranged in such a way that the light on the work surface of the craftsmen falls from behind or from the side, and the distance between the burners at the work places should not be less than 125 cm.

In addition to the workroom, several utility rooms will also be required, which may be smaller in area, as long as they are isolated from the main one. In one of these rooms, grinding, grinding and drilling machines, as well as a machine for cutting tubes and blanks are installed, in the other - compressors, and in the third - fume hoods (calibration work will be carried out here). Please note: windows and doors in all rooms, including working and utility rooms, must open outwards. In addition to the equipment, racks are installed in the working room, where blanks, tools and finished products will be stored, as well as special vertical racks for storing glass jet. Such racks and racks can be made independently.

Gas, oxygen and air are supplied to each workplace. In most cases, glassmakers use pressurized city gas or bottled propane gas. In the latter case, all gas cylinders are placed outside the building where the workshop is located, in a metal box, which is locked. From the cylinders, gas is supplied through a reducer through pipes to the glass-blowing workshop. Oxygen from cylinders is also supplied to the working room through metal tubes. high pressure on the switchboard, which must be placed on one of the walls of the workshop. From the distribution board, oxygen is supplied to each work table through a reducer. Gas, air, oxygen are supplied to the burners through the corresponding branches on the line through high pressure rubber hoses. As a rule, these hoses are fixed under the worktops and lead out through holes or cutouts in the table top near the burner. All gas and oxygen supply must be coordinated with Gosgortekhnadzor. Pipelines supplying gas, air and oxygen to the table are mounted on the wall and painted in various colors (red, yellow, green).

The indoor workshop should be equipped with without fail exhaust and supply ventilation. Above each table, it is necessary to install an umbrella connected to an exhaust ventilation duct to remove smoke and combustion products. Centrifugal fans can be used as forced ventilation. It is optional, but highly desirable, to install air conditioners in your workshop, which will help maintain a comfortable air temperature during the hot season.

Ready-made ideas for your business

In addition to daylight, the workshop will also need to be equipped with fluorescent lamps. For certain types work, you can use special table lamps with a reflector.

In one of the utility rooms, compressors of sufficient power are installed, which will help to provide excess air pressure at the burner. For uniform air supply, a receiver or a strong sealed container or, in extreme cases, an empty one is used. steel cylinder. In the latter case, two threaded holes must be drilled in the cylinder, into which short pipelines are then screwed. At one (upper) outlet, a pressure gauge and a spring-loaded safety valve of the PSK type are mounted.

Ready-made ideas for your business

When working with oxygen, the system through which air is supplied to the workplace must be equipped with oil filters.

Metal tables for muffle furnaces are installed in the room adjacent to the workshop. It is necessary to put sheet asbestos on the metal surface of the table, on which, in turn, muffle furnaces with different capacities of the furnace space are placed (the best option is with automatic temperature control). This equipment is used for roasting finished products. Above the table where the muffle furnaces are located, a marble shield with magnetic starters for each furnace is installed. If the layout does not provide for an adjacent room, then the stoves can be installed in the workshop room.

There are several grinding machines in the room for the mechanical processing of glass (four furnaces are enough for the above indicated footage), a glass cutting machine with a corundum or diamond disc, desktop drilling machine for drilling holes in glass. In addition, it is necessary to have a sharpening machine with a vertical corundum wheel for sharpening tools.

In the calibration room, in addition to fume hoods, all the necessary utensils and reagents for applying marks are stored. According to the requirements, both in the workers and in the utility rooms of the workshop there must be fire fighting equipment, a box with sand and a shovel, foam and carbon dioxide fire extinguishers. In addition, do not forget to purchase a first-aid kit with dressings and medicines in the workshop to provide first aid to injured workers.

Ready-made ideas for your business

To organize such a workshop, it will take from 3 million rubles. Payback periods are from 1.5 years. An additional source of income (in addition to the sale of glass products) can be guided tours, master classes and courses for those who want to learn the basics of working with glass.

Manufacture of glass products by industrial method

Medium and large enterprises for the production of glass products carry out a full production cycle. The manufacturing process here begins with the preparation of the mixture - a mixture of different materials, selected in accordance with the type of glass being produced, which is subjected to careful processing. The next step is to melt the glass. This is a very important operation, on which the quality largely depends. finished products. Glass melting is carried out in special glass furnaces with a gradual increase in temperature from 700 ° to 1450 - 1480 ° C. After melting, the glass mass is slightly cooled, and then products are produced or formed from it by various methods. There are several basic molding methods, among which are blowing, press-blowing, pressing and centrifugal casting. Blowing can be carried out by mechanized, vacuum blowing, manual (in molds) and free methods. For each of these methods, separate equipment is used. For the manufacture of simple souvenirs at such enterprises, the first two methods are used. Hand blowing into molds, which is done with a glass tube, is a much more laborious and costly process, so this method is used here for the manufacture of complex products. Free blowing (the so-called gut, or Guten technique) is a free molding of a product (without using a mold). In this case, a ball of glass is collected on the tip of the tube, which is then blown through the tube into a ball with continuous rotation and constant correction of the ball with wooden blocks. The resulting workpiece is removed from the tube and placed on an iron rod for further processing. The nature of processing depends on what is planned to be obtained as an output. The master can open the upper part or roll out the lower part of the workpiece to obtain one form or another. Distinctive features of blown products include a small wall thickness of the product, more complex and diverse shapes than with other production methods, and high transparency. Centrifugal casting occurs under the action of centrifugal forces. The pressing process is carried out in two stages. First, the product is molded in molds, and then it is given its final shape under the influence of hot air. Such products have thicker walls, are not so transparent, but are often decorated with relief ornaments.

After molding, regardless of the method used, glass products go through the firing procedure - they are kept in furnaces at a temperature of 530-580 ° C and slowly cooled. This allows you to significantly increase the thermal and mechanical stability of the material. Then the finished products are processed (the tops that adjoined the blow tube are cut off, the edges, bottom and neck are aligned with the help of grinding) and decorated with paints and various elements. There is a wide variety of options for decorating glassware. So, the methods of decorating hot glass (that is, before the finished product cools or even during its production) include color, satin glass, iridescence, crackle, sulfide glass, glass thread decoration, colored embankment. A color is a decoration made of colored glass, which is applied to the surface of colorless glass. Satin glass is a combination of milky and colored glass using complex shapes with protrusions and recesses of various sizes. The technique of sulfide glass is to obtain marble-like and opal bands of different color shades. A colored embankment is multi-colored influxes on the background of colorless or colored glass. Irrigation refers to the hot treatment of glassware with tin or silver salt vapors with the addition of strontium compounds, which form a thin iridescent film on the surface of the material. Crackle decoration consists in the formation of thin cracks in colorless or colored glass mass, creating the effect of an antique (artificial aging). When decorating with glass thread, the finest colored threads and stripes are placed on the surface of the glass mass or inside it in the form of a free-form pattern, parallel stripes, spirals, etc.

Finished products are decorated by mechanical methods (for example, engraving), painting, metal films, luster paints, chemical methods (etching), etc. Engraving is a matte pattern with a large number of small contour details, which is applied using copper discs of various diameters and abrasive mass. When etching, the pattern is applied using mixtures of solutions of hydrofluoric and sulfuric acids, which dissolve the glass. There are several types of etching: simple, pantograph and deep. In the first case, glass products are covered with mastic containing wax or paraffin, then a pattern is applied using special equipment equipped with needles, and then an etching mixture for 15-20 minutes, after which it is washed off with water. So they do, basically, a pattern with rings, zigzags and spirals. With pantograph etching, more complex ornaments can be made, and thick glass products are decorated with deep ones. Glass products can also be painted using brushes and stencils with special silicate paints, followed by firing at a temperature of 550 °C. To create gold ornaments, the technique of decorating with a metal film is used. It consists in applying liquid (twelve percent) or powder gold to colorless and colored glass on a frosted and etched relief surface. In this case, gold is applied with a thin brush, then the product is dried and fired to fix the ornament. Also, glass can be coated with luster paints, followed by firing to obtain a shiny metallic film on its surface. Patterned carvings are often applied to glass using grinding wheels, followed by polishing, or moldings - liquid glass in the form of droplets, followed by blowing it to form the desired shape.

Certain requirements are imposed on the quality of glass art products. It must comply with approved reference samples and the requirements of regulatory and technical documentation. These products are sorted according to appearance, the degree of permissible defects and physical and mechanical properties. At the same time, defects in glass mass, production and processing of decoration are taken into account. During the quality assessment, specialists take into account the type, size, location of the defect and the size of the product itself. Depending on the raw materials used, the type of product and its purpose, glass art products are sorted into grades, the number of which is regulated by standards, and labeled with stickers indicating the manufacturer, trademark, standard number.

Since glass is a very fragile material, products made from it are carefully packed in cardboard boxes with pre-wrapping in soft paper or in foam cases. Special requirements apply to the transportation of such products. It is carried out in boxes filled with shavings and other soft materials, with warning labels. But special conditions such products do not require storage in warehouses. It is enough that the room is dry and closed. Do not make the racks too high. When placing products, take into account its weight: heavy products are placed on the lower shelves, and light products are placed higher.

To organize such a production, special expensive equipment will be required: an automated line with a raw material supply channel, “scissors” for cutting molten glass, an automatic press into several forms, a press hydraulic drive station, a molding machine with an air cooling system, a system for extracting a pressed product from a molding machine, an oven ejector annealing machine, paint coating machine, drying machine (for drying paint on products), glass grinding and washing equipment, blowing equipment, etc.

The cost of such equipment is several tens of millions of rubles. The exact price depends on the configuration (determined by the range of products produced and the planned production volumes), as well as the manufacturer (the most popular because of the price-quality ratio is Chinese equipment). To accommodate the line, a large production area will be required - at least 1000 square meters. meters. Annealing Furnace and drying chamber should be located in a separate room, which, meanwhile, communicates with the workshop. In addition, we need an area for a packaging shop for finished products and a separate room for a warehouse. To work in such a production, you will need at least 5-7 people, plus a foreman-technologist and a supervisor for a shift. Most of enterprises work in two or three shifts (with a maximum load). Payback periods are from 2.5 years.

Manufacturers of glass souvenirs and gifts sell their products through wholesale companies, various retail chains, individual stores(including online stores, although in this case special individual packaging is required for safe transportation), outlets and even markets. In general, this product is in consistently high demand, although there are some influences of the seasonality factor. So, most orders fall on pre-holiday periods (before the New Year, March 8). In the summer months, manufacturers of glass souvenirs do not complain about a drop in sales, their “geography” simply shifts. During this period, souvenirs are most actively sold in the south of the country. Many companies even release special collections with a nautical theme for the holiday season.

723 people are studying this business today.

For 30 days, this business was interested in 43499 times.

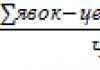

Profitability calculator for this business

Instruction

To manually blow out any figure, you need to attach the prepared form to the end of the tube. In which it is necessary to blow glass. You need to do this quickly enough, otherwise the glass will harden, and nothing will work. Therefore, in the so-called manual blowing, many use units that constantly keep the glass in a liquid state, that is, heat it up. In general, it is this blowing method that is used when it is necessary to obtain a thin material, and not a thick one. Because only a person can correctly adjust the exhalation force so that the product is thin and perfectly transparent.

To make a figurine from different parts connected to each other, you need to blow them all in turn. And then, when the glass is already slightly hardened, solder them together with a heated burner.

If you want to apply a pattern to the glass you blow, then you need to take care of additional tools. These can be scissors (regular and diamond-shaped), tweezers, tongs and much more. With the help of scissors, you can put edges on the glass, cut out a certain pattern. Using tweezers, you can twist the product so that it becomes original and unusual. The main thing is to have time to do all this, while the glass is still straightened and amenable to alterations. Now it remains only to color it, and the original souvenirs are ready.

The art of glass blowing is a complex, painstaking process. A similar technique is similar to the first century BC, it appeared in Sidon (now coastal Lebanon). From there the art spread to the Roman Empire and then to other parts of the world. The art of glassblowing is still practiced today, and involves mastering a host of complex techniques. The most important thing in the work of glassblowers is the performance of work with high level precision and accuracy.

The process begins when a 4-5 lb. tube enters the furnace, where the glass is melted at 2200 degrees Fahrenheit (lava temperature).

This process is called collection. Once collected, glassblowers dip the blowpipe into hot glass until a decent-sized blob is concentrated at the end. This is very difficult moment because the glass has the consistency of honey and drips easily from the end of the pipe.

In the next step, the glassblower starts blowing air into the pipe, creating a small air bubble inside the molten glass. This is a very delicate process: if the artist blows too hard, then his work will collapse.

One of the most difficult aspects of blowing is keeping the temperature at the right level. By maintaining the temperature, the artist can shape the glass into whatever shape he has in mind. Thanks to the traditions that are passed down by glassblowers from generation to generation, this art never ceases to attract and conquer our attention.

I always thought that blowing glass products is difficult industrial production. But it turns out that it is possible to organize it in a large city apartment or, for sure, in a country house. There would be enough electricity. It was from the apartment that he began at the time your art with glass Egor Komarovsky. Egor is an enthusiast, self-taught, a very enterprising and creative person. I recently had the opportunity to visit glass-blowing workshop "Steklou" and see how a vase is blown out of a drop of glass.

In general, according to his initial education, Egor Komarovsky is an international logistician, but he did not stay at office work for a long time, preferring it to creative work. He started with a blacksmith, and then turned his attention to glass. In a rented apartment, he and his wife began to heat the village, wrap it in foil and study it in every possible way, trying to figure it out. Then they began to engage in glass fusing - this is the fusion of glasses with each other and then the finished product is sintered through the mold (for example). Engaged and stained glass. Both productions are now more or less widespread and competitive on the market.

2

But glass blowing, on the contrary, few people do. There were many glass-blowing factories in the Union, but almost all of them were closed, there are almost no private workshops. There is one institution in Moscow, in St. Petersburg, the Mukhinskoye School, but none of them took Yegor either as a student or as a worker, fearing imaginary competition. In all of them, mostly "old cadres" 60+ work, there are almost no young specialists.

3

I only managed to work a little on personal agreements with individual craftsmen. This, plus a theoretical study of the issue, is a boon on the Internet(but not in Runet) Now there is a lot of information, as well as my own practice, which allowed me to master the technique. The chosen strategy also inspires respect - to take in the order for manufacturing work a little more complicated than it did before. Prepayment taken, motivation rises - like it or not, you need to do it. Sometimes it was necessary to redo the product 15 times before a satisfactory result was achieved.

4

Whereas abroad this direction is very common and even popularized. They make home glass melting furnaces, teach everyone who wants it - you can easily organize a home mini-production. Komarovsky had to make his own stoves on his own (buying foreign ones is very expensive).

5

In total, three ovens with different temperatures are needed for production. All of them are electric, 6 kilowatts each. There is another gas furnace "cuckoo" for heating the material in the process of its molding.

6

There are a lot of all sorts of colored and shiny beauties in the workshop. And the vases here are literally in bulk.

7

This is approximately the same vase that will now be blown out of a drop of glass.

8

The glass itself is also of American origin - special for blowing. We do not produce such things, and large-scale productions brew glass for themselves. Colored glass ordered in the form of plates, and transparent in the form of such drops. Drops are easier to work with.

9

First, the glass is melted in a ceramic pot at a temperature of 1600 degrees.

10

They lower the glass blowing tube and take everything that has stuck to the end of the tube from the furnace. They blow out a little. A glass blowing pipe, or blown pipe, is a hollow pipe about 1.5 meters long with a brass mouthpiece.

11

And they roll forming the required shape. Forming stage.

12

Glass is periodically heated in the "cuckoo" so that it retains its elasticity. Glass begins to soften at 650 degrees and above.

13

Next, we lower the tube into the glass again, stick new glass on it, blow it out, and mold it. This is the so-called free blowing technique. In addition to it, there are other methods

14

At a certain point, we stick strips of colored glass on the workpiece. They were pre-prepared - they took strips of colored glass and sintered them together into one plate. Primarily stuck platinum on the workpiece.

15

Additionally, parts were sintered in the "cuckoo".

16

And now we carefully form by bending the sides.

17

18

19

And then all the same stages - blowing, molding, heating, etc. Sometimes, however, it is necessary to slightly cool the workpiece with a moistened newspaper. It is necessary to strictly observe the temperature balance, as well as constantly monitor the dimensions, wall thickness, quality. A tricky business that requires good skills.

20

When the lights are off, the workshop appears in a beautiful fairy-tale form. .

21

Molding is also done using the force of gravity. They tilted it to one side - the workpiece began to deform downwards, the glass flows down.

22

23

24

When the vase has "grown" almost to the required size, the workpiece is once again dipped in liquid glass to form a transparent protective layer under loading.

25

After about 1.5 hours, the vase is almost ready. Now they take another glass-blowing tube, dip it into the glass and solder it to the vase from the opposite end. The old tube is removed, and in its place, the neck of the phase begins to form. The glass is soft, so we expand the hole with tweezers, bend the edges and give the desired shape.

26

This is how it turned out, only after cooling the colors will be different. White will remain white, blue will become azure, and red will become yellow.

27

And the last stage is cooling, or annealing - also a very important process. The thicker the glass, the longer it takes to cool. Centimeter products are cooled for days and even months. Approximately 12 hours are sufficient for these vases. Below 517 degrees, tensions begin to appear in the glass, and up to 370 degrees it is necessary to cool very slowly and carefully, then the cooling rate increases slightly. After annealing, the vase will need to be sanded and everything will be ready.

The good news for everyone is that Egor Komarovsky faced with all the difficulties of learning the craft, he decided to change the situation and already conducts courses and master classes for everyone who wants to learn glassblowing. There are also excursions for schoolchildren. 2 hours of classes cost 4000 rubles and during this time you will be able to understand whether it is interesting for you or not. If yes, then you can continue your studies, and then come and make some products for yourself (if you think that you don’t need your own workshop). In general, plans for education are big - production will soon move to new site where it will be possible to conduct larger excursions and master classes. Yegor also advises many glassblowers at other industries, preferring not to make the required product himself, but to show how it is done, train, and then they can do it on their own. That is, Komarovsky took on a very large and grateful mission of enlightenment and education, which, given the shortage of masters and information now in Russia, cannot but arouse great respect.

Thank you traditionally spbblog

in the face Zhenya

for invitation.

Other stories and photographs can be read and viewed at Zhenya

Katerina

,

What is currently impossible to do with your own hands? Whether it's an ordinary craft, a wardrobe item, furniture and more. How to make glass at home? - It would seem that glass is melting, it is unrealistic. AT modern world nothing is impossible. The main thing in this business is desire. And in this article you will find detailed step by step algorithm so entertaining and interesting lesson how glass is made.

What is known about glassmaking?

It is known from history that glassmaking is a very ancient process. How it's done? According to the time frame, it refers approximately to the period before 2500 BC. Previously, such a rare and valuable occupation in our time has been replaced by the widespread production of this material.

Glass products are found everywhere. They are used as containers, household and decorative elements, insulators, reinforcing fiber and other things. Glasses differ only in the constituent material that is used for manufacturing. But the process itself is almost the same.

The main materials you will need:

- the main element is quartz sand (silicon dioxide);

- sodium carbonate or soda;

- calcium oxide, she is lime;

- furnace for melting glass;

- other salts and oxides that can be used additionally on an individual basis (oxides of aluminum, iron, magnesium, lead and calcium or sodium salts);

- protective clothing;

- grill;

- charcoal;

- forms and other elements for shaping;

- refractory crucible.

Methods for making glass using a furnace

The first way to solder glass at home is to use an oven.

Acquisition of quartz sand:

- This material is the basis for the production of glass. Glass, in which there are no impurities of iron, has its advantages - it is light. What can not be said about the glass in which it is present. It will give off greenery.

- It is important to wear a mask before starting work. Quartz sand is fine-grained and easily enters the nasal cavity and further into the lungs. This, in turn, will irritate the throat.

- You can easily buy quartz sand in a specialized online store. Its cost is low.

Important! The cost of the approximate amount that will be needed will be around $ 20. e. In the future, you can buy it up to a ton, the approximate cost of which will be 100 c.u. e. This is if you plan to work on an industrial scale.

- It happens that finding high-quality sand is not so easy, and it contains more than the amount of impurities. Dont be upset. In this case, manganese dioxide will come to the rescue. It should be added in small amounts. If in your idea it is glass with a greenish tint, then absolutely nothing needs to be done. Leave everything as it is.

Addition of carbonate and calcium oxide:

- The carbonate in this case lowers the production temperature of industrial glasses. At the same time, it causes glass corrosion with the participation of water. To avoid this, it is necessary to additionally introduce lime or calcium oxide into the glass.

- Magnesium or aluminum oxides are used for glass durability. As a rule, these inclusions occupy a small percentage in the glass composition. The figure is approximately 26-30 percent.

Addition of other chemical elements:

- This method of making decorative glass at home requires the use of lead oxide. It gives shine to crystal, its low hardness, makes it accessible to cutting, and gives a low temperature of melt formation.

- Lanthanum oxide can be found in eyeglass lenses. It has a refractive property.

- With regards to lead crystal, it can contain up to 33 percent lead oxide.

Important! The more lead, the more dexterity is needed to shape the molten glass. Based on this, many glassblowers prefer a smaller amount of it.

- Iron impurities in quartz glass give it a green tint. In this case, iron oxide is added to increase the greenish tint. This also applies to copper oxide.

- Yellow, amber, and even black can be obtained with a sulfur compound. It all depends on the amount of carbon or iron added to the glass charge.

The main stages of glass production:

- Place the mixture in a temperature-resistant crucible. The latter should be as resistant as possible to the temperature that will be in the oven. It can vary from 1500 to 2500 degrees. It depends on the additives.

Important! There is one more important requirement for the crucible - it must be such that it can be easily fixed with the help of metal tongs.

- Melt the mixture to a liquid consistency. For industrial silicate glass this can be done in a gas-fired oven.

Important! There are also electric, muffle and pot furnaces. They can be made with special glass. Please note that quartz and sand, which do not contain additional impurities, go into a glassy state when the temperature in the furnace is 2500 degrees Celsius. If sodium carbonate is added to the contents, this is ordinary soda, then the temperature will drop to 1500 degrees.

- Carefully monitor the consistency of the glass. It is important to remove all bubbles from it in a timely manner. This can be achieved with regular stirring to a uniform density. It is also necessary to add one of the elements - sodium chloride, sodium sulfate or antimony oxide.

- Shape the glass. To do this, use one of the following methods.

- The simplest thing is to pour the melted glass into a mold and wait until it cools down. With this method, many optical lenses are created. Previously, this method was used by the Egyptians.

- Place the finished molten glass in a bath containing molten tin. The latter acts as a substrate. Next, you need to blow it with compressed nitrogen for shaping or polishing. Another way is to collect at the end of a hollow pipe required amount glass and, turning the pipe, blow it out.

Important! Glass made using this method is called float glass. It has been produced since the early 1950s.

- Leave the glass to cool down. It is important to place it in a place where it will not be damaged, water, dust or, for example, leaves will not spoil it. Keep in mind that when in contact with cold objects, it will crack.

- The final step of this method to make glass at home will be glass annealing. This method of heat treatment will give strength to the material. When using it, all point sources of stress that can be encountered during the glass cooling process will be removed.

Important! Upon completion of this work, additional coatings can be applied to the glass to increase durability and strength. Also can be laminated.

- Unannealed glass is less durable.

- As for the temperature for finishing work, it depends on the exact composition of the glass - from 400 to 550 degrees Celsius.

- The cooling rate of the glass depends on the size. Large glass items must be cooled slowly. Smaller things go faster.

Method for making glass using a brazier

The second way to make glass at home is a charcoal roaster. Let's take a look at everything step by step in this case.

Equipment for work

First you need to make an oven. A barbecue grill is perfect for this. It is important that it is heated with charcoal. In this case, in order to melt quartz sand into glass, the heat that coal generates when burned is used. Again, the cost of this material is not too high. They are widely available.

Important! Grill use standard size. Better if it is in the form of a dome. The main qualities that he should have are the presence of thick walls and good strength. If the grill has a ventilation hole, usually located at the bottom, it must be opened.

However, there may be small obstacles in this method. Even if there are very high temperatures, it is not always possible to melt it with ease. To do this, before starting the process, you need to add lime, borax or washing soda to the sand. The amount of additives should not exceed ⅓-¼ of the volume of sand.

Important! Remember that these additives significantly lower the melting point of the sand.

Glass Formatting

For blowing glass, prepare a long hollow metal tube. In order to pour glass, a mold is needed. It should be dense and should not melt from hot glass. Use, for example, graphite.

Important! Using this method it must be remembered that the heating of the grill is much higher than its normal heating. It is possible that the grill itself may melt. Therefore, in the manufacture of glass in this way, you need to carefully and responsibly perform all actions. Negligence can result in serious injury or even death.

Security measures:

- Place a large amount of sand and a fire extinguisher near the work area.

- All work must be done outdoors.

- The floor must be concrete, for example.

- Stay away from the grill when melting glass to protect yourself and your clothing from high temperatures.

- Remember to wear protective clothing. These are fire-resistant clothing, oven gloves, a high-strength apron over clothing, and a mandatory welding mask.

- Also in this method you will need a vacuum cleaner. It will act as a coal blower. We arrange it as follows: we attribute the body to a sufficient distance. We fix the hose to the ventilation hole, which is located below. It may need to be bent to give the desired shape. You can fix it to one of the legs of the grill. The hose must be fixed firmly and not move.

Important! If the opposite happened, then in no case do not approach him, because he is very hot. Next, you need to turn off the vacuum cleaner and look at the position of the hose. It must be aimed exactly at the vent hole.

Operating procedure:

- Place on the inside of the grill charcoal. It is necessary to put it in two or even three times more than for roasting meat. Well, if it is filled almost to the brim.

Important! Use hardwood charcoal. It burns faster and better than briquetted.

- In the middle of the bowl, place a cast-iron container or a crucible with sand.

- Carefully study the packaging of the coal used. Fire it up in the right way. There is coal that ignites directly by itself, and there is material for which ignition fluid is used. Wait for the flame to spread evenly.

- Wait until the coal is ready for further work. The readiness of coals can be determined by color. They will be orange.

- The next step is to turn on the vacuum cleaner. This is necessary so that the coal is blown.

Important! Coal exposed to air flow can be heated to very high temperatures. Up to about 1100 degrees Celsius. This must be taken into account when near the stove. Ascending flashes may appear from it.